After driving my Z for hundreds of miles thorough Europe this past summer to attend the Centennial celebrations, I thought a full check up was in order after the car arrived home to New York – USA. A compression test told the sad story of two cylinders with very low compression. A visual inspection showed that the rear seal was leaking, the transmission bell-housing was leaking, motor mounts were saggy. The clutch, that had been an issue in Europe, also needed looking after. With winter in full force I thought it would be a good time to visit my favorite Alfa shop while they were slow. With all this work to be done the easiest thing to do was is to pull the motor and transmission.

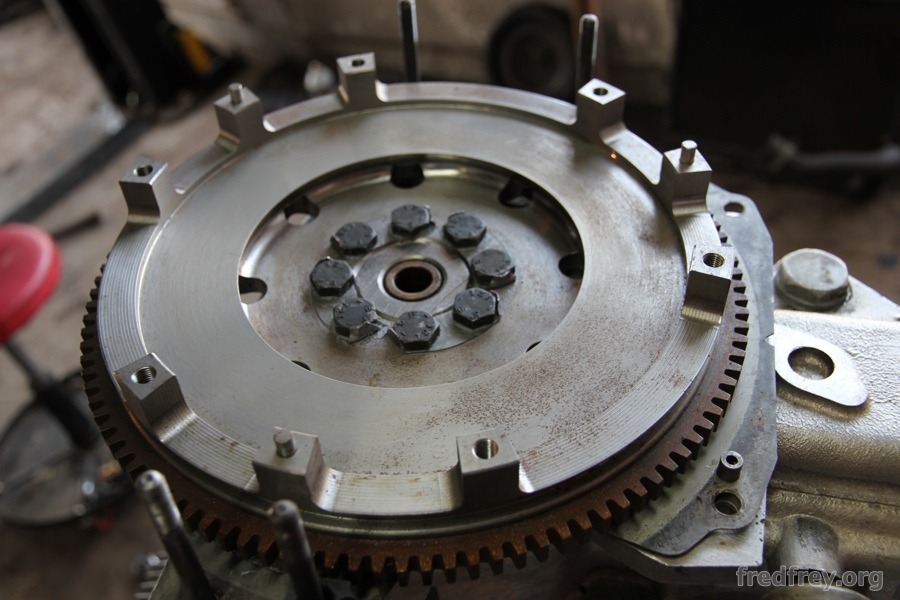

Work done: Replace; transmission mount, clutch, pressure plate, flywheel (Alfaholics lightened steel), front and rear seals, motor mounts. A stainless exhaust system was ordered from Alfaholics as the existing system had some small holes in the manifold. Also from Alfaholics came more aggressive cams and larger intake valves. The main and rod bearings were checked and looked fine so the bottom of the engine was left intact. The cams were discovered to be very worn with sharp lobs that damaged the followers. The lower chain was very slack so a racing change was installed along with a new water pump. The reason for poor compression was determined to be poor seating valves. The head was sent out, valve seats cut and some modification was necessary to accommodate the taler lobs on the performance cams. And finally with the engine out, it was easy work to clean and touch-up the engine bay.